Epoxy Flake Floor Coating Systems are usually applied as 5-coat system which include the prime coat, basecoat and clear top coat. They provide a beautiful granite look like finish and they are available in a large variety of colours to choose from with infinite possibilities to achieve optimal appearance and texture qualities with a resinous flooring or wall coating system to match any décor. It is an extreme durable system which is brilliantly coloured and will enhance the aesthetic qualities of seamless flooring. Therefore these coatings are used in many environments such as residential, commercial and industrial applications where a long lasting solution to floor maintenance and a hard wearing protection is required. This product is easy to apply.

Epoxy Flake Floor System 1:

Epoxy Flake Floor System 1:

| Prime Coat | Water-Based Epoxy WEP50 HB™ |

| Base Coat | Water-Based Epoxy WEP50 HB™ |

| Flake | Colour Flake® |

| 1st Top Coat | Urethane 2Pack™ |

| 2nd Top Coat | Urethane 2Pack™ |

Epoxy Flake Floor System 2:

Epoxy Flake Floor System 2:

| Prime Coat | Water-Based Epoxy WEP50 HB™ |

| Base Coat | Water-Based Epoxy WEP50 HB™ |

| Flake | Colour Flake® |

| 1st Top Coat | Durathane SP40™ |

| 2nd Top Coat | Durathane SP40™ |

One Day Epoxy Flake Floor System:

One Day Epoxy Flake Floor System:

| Prime Coat | Water-Based Epoxy WEP32™ |

| Base Coat | Polyurea PU100™ |

| Flake | Colour Flake® |

| Top Coat | Polyaspartic PS90™ |

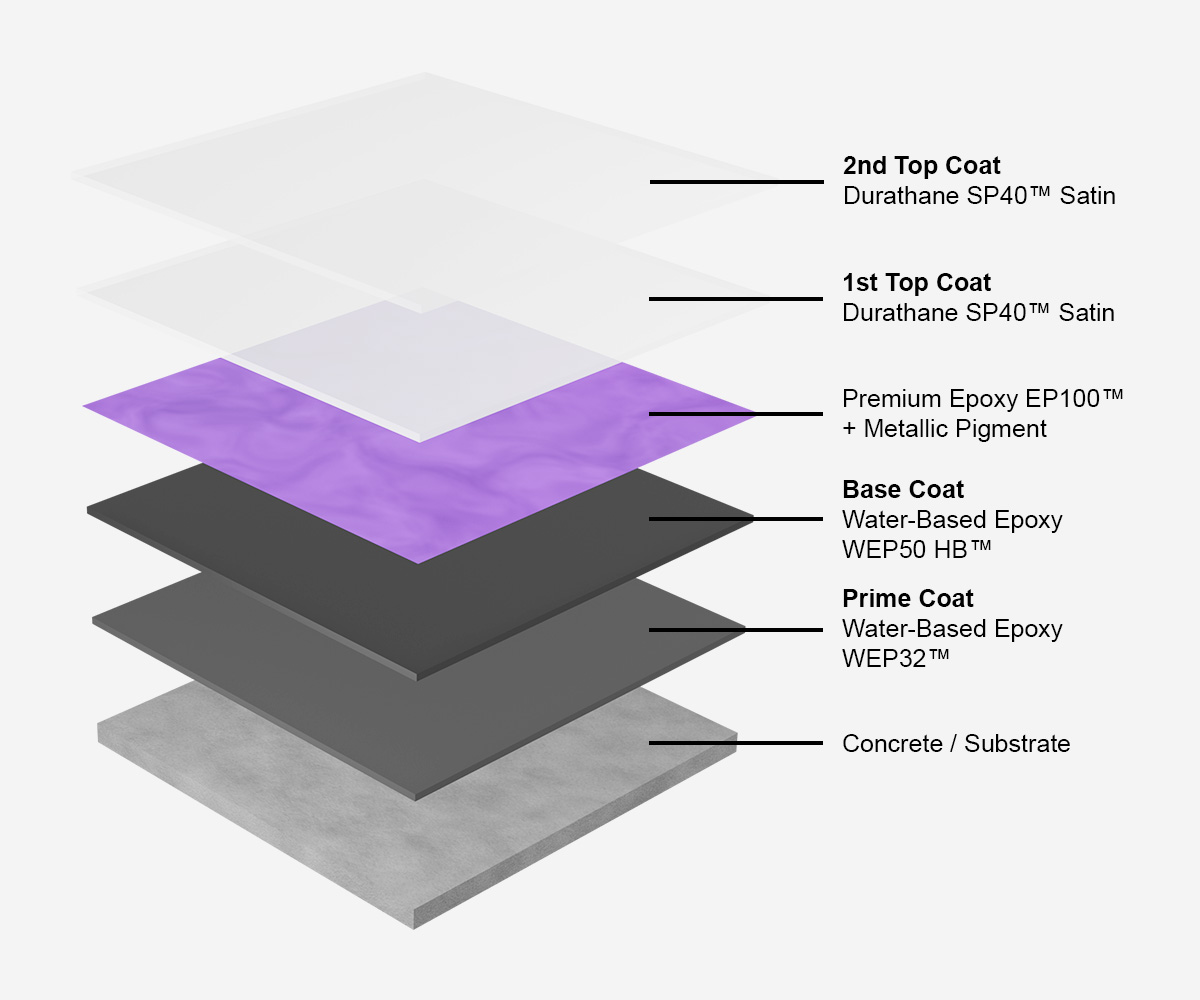

Metallic Epoxy Floor Coating System are usually applied as 5-coat system which is truly unique in appearance with an astonishing glass-like finish and they provide that unbeatable wow factor. We always recommend prime coating the surface to close off the capillaries within the substrate. Then an opaque basecoat is applied preferably in black, but it also depends on your metallic epoxy coating colour you have chosen and the finish look you require. This coating can be used in residential, commercial and industrial environments. This product is easy to apply, and easy to clean and maintain.

Metallic Epoxy Floor System 1:

| Prime Coat | Water-Based Epoxy WEP50 HB™ |

| Base Coat | Water-Based Epoxy WEP50 HB™ |

| Metallic Epoxy | Premium Epoxy EP100™ + Metallic Pigment |

| Top Coat | Polyaspartic PS90™ |

Metallic Epoxy Floor System 2:

| Prime Coat | Water-Based Epoxy WEP50 HB™ |

| Base Coat | Water-Based Epoxy WEP50 HB™ |

| Metallic Epoxy | Premium Epoxy EP100™ + Metallic Pigment |

| 1st Top Coat | Durathane SP40™ Satin |

| 2nd Top Coat | Durathane SP40™ Satin |

Epoxy Floor Coating Systems are usually applied as 2-coat or 4-coat system which includes the prime-coat and basecoat. Alternatively you can add a 3rd epoxy coat or a clear top coat, it all depends on the purpose of the coating, the environment and the substrate. Epoxy Floor Coating Systems are used in various areas and environments to protect the concrete surface from spillages, pollution, and chemicals which can damage the substrate. They are extreme durable and provide maximum protection due to be a seamless finish. Epoxy Floor Coatings are used in many environments such as residential, commercial and industrial applications where a long lasting solution to floor maintenance and a hard wearing protection is required. This product is easy to apply, and easy to clean and maintain.

Epoxy Floor Coating System 1:

Epoxy Floor Coating System 1:

| Prime Coat | Epoxy EP200™ |

| Base Coat | Epoxy EP200™ |

Epoxy Floor Coating System 2:

Epoxy Floor Coating System 2:

| Prime Coat | Water-Based Epoxy WEP32™ |

| Base Coat | Polyurea PU100™ |

| Top Coat | Polyaspartic PS90™ |

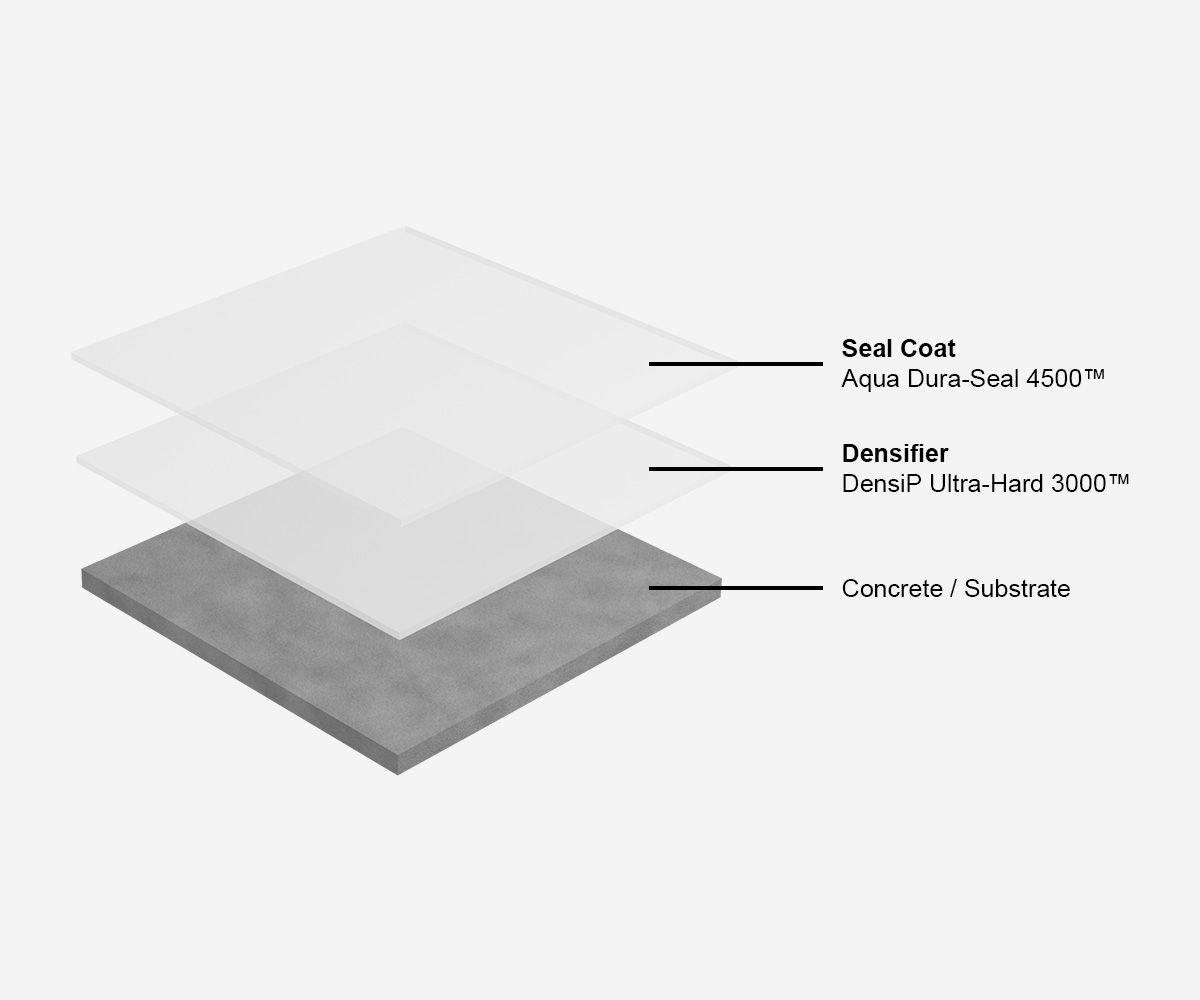

Polished Concrete Coating Systems are carried out in multi-step mechanical process, with or without aggregate exposure. The most popular finish is grinding the concrete surface to expose aggregates or stones in the concrete and showing the natural beauty of stone. Polished Concrete Floors are extreme durable, low in maintenance and create a unique and stylish look with maximum protection due to be a seamless finish. There are two types of polished concrete. The first one is called Grind & Seal, which is followed by the application of a topical surface sealer. The second is called Mechanically Polished Concrete where a densification of the concrete surface is carried out during the process with mechanically polishing the concrete in stages with finer diamond tools, which is then usually followed by a penetrating sealer. Polished Concrete Flooring are used in many environments such as residential, commercial and industrial applications where a long lasting solution to floor maintenance and a hard wearing protection is required.

Polished Concrete Coating System 1 – Grind & Seal:

| Prime Coat | Aqua Urethane 2Pack™, or Urethane 2Pack™, or Durathane SP40™ |

| Main Coat | Aqua Urethane 2Pack™, or Urethane 2Pack™, or Durathane SP40™ |

Polished Concrete Coating System 2 – Mechanically Polished:

| Densifier | DensiP Ultra-Hard 3000™ |

| Seal Coat | Aqua Dura-Seal 4500™ |

DISCLAIMER:

The Durable Concrete Coatings® Epoxy Supplies floor visualizer presents a preview of how a floor and its surrounding space might appear. Please note that the actual outcome may differ in terms of colours and proportions, influenced by variations in devices, monitors, and their settings.

This colour chart and accompanying swatches serve solely as a GUIDE. The colours shown and/or printed are replicated to the best of modern printing capabilities. However, the final colour may differ based on factors such as product variations, surface discrepancies, substrate types, job conditions, textures, and finishing techniques. It is advisable to apply a sample on a small section of the substrate before full application to ensure the desired colour accuracy.

Durable Concrete Coatings® Pty Ltd assumes no liability or responsibility for colour discrepancies.